LEVAJOINT Waterstop is a specially formulated polyvinyl chloride ( PVC) compound manufactured from virgin materials that fulfill all properties desirable for a waterstop.

The material is tough, flexible, resilient, chemically inert, is not affected by weathering, low temperatures, or constant immersion in water. It will withstand rough treatment during installation, yet, is relatively easy to install and splice.

LEVAJOINT Waterstop is unaffected by concrete additives and most water solutions of organic chemicals.

LEVAJOINT Waterstop is available in different shapes, types and (TPV / TPE-R) for Oil Industry.

Flexible

Flexible Waterstop

Chemical inert

Chemical Inert Material

Weather Proof

Not affected by weather

Water Immersion Proof

Not affected by water immersion

Robust

Tough material

|

LEVAJOINT PVC WATERSTOP SPECIFICATIONS |

||

| PROPERTY | STANDARDS & NORMS | NOMINAL VALUES |

| SPECIFIC GRAVITY | ISO 2781 | 1.37 |

| WATER ABSORPTION | ASTM D570 | 0.13% |

| TENSILE STRENGTH LONGITUDINAL | ASTM D638 | 13.3 MPa |

| ELONGATION AT BREAK | ASTM D412-87 METHOD A | 445% |

| HARDNESS SHORE A/10 | 72 ± 3 | |

| STIFFNESS-IN FLEXTURE | 920 PSI | |

| TEAR RESISTANCE | ASTM 1004 | 333N |

| MODULUS OF ELASTICITY | 800PSI | |

| LOW TEMPERATURE BRITTLENESS | ASTM D746-79 AT - 26ºC | PASSED |

| COLD BEND ¼" MANDREL AT - 10ºC | PASSED | |

| LOW TEMPERATURE FLEXIBILITY AT - 20ºC | PASSED | |

| LOW TEMPERATURE IMPACT AT - 20ºC | ||

| 24 HOURS | 0.082% | |

| 48 HOURS | 0.320% | |

|

LEVAJOINT TPV / TPE-R WATERSTOP SPECIFICATIONS |

||

| PROPERTY | STANDARDS & NORMS | NOMINAL VALUES |

| HARDNESS SHORE A (±3) | ASTM D-2240 | 85 |

| TENSILE STRENGTH | ASTM D-412 | 2100 psi (14.47 MPa) |

| ULTIMATE ELONGATION | ASTM D-638 | 480% |

| 100% MODULUS | ASTM D-638 | 1050 psi (7.24 MPa) |

| BRITTLE POINT | ASTM D-746 | -69°F (-56°C) |

| STRESS @ 100% ELONGATION | ASTM D-638 | 1000 |

| OZONE RESISTANCE | ASTM D-1171 | PASSED 460 pphm |

| PEEL STRENGTH @ 23°C | ASTM D-816 MOD. | 22 pli |

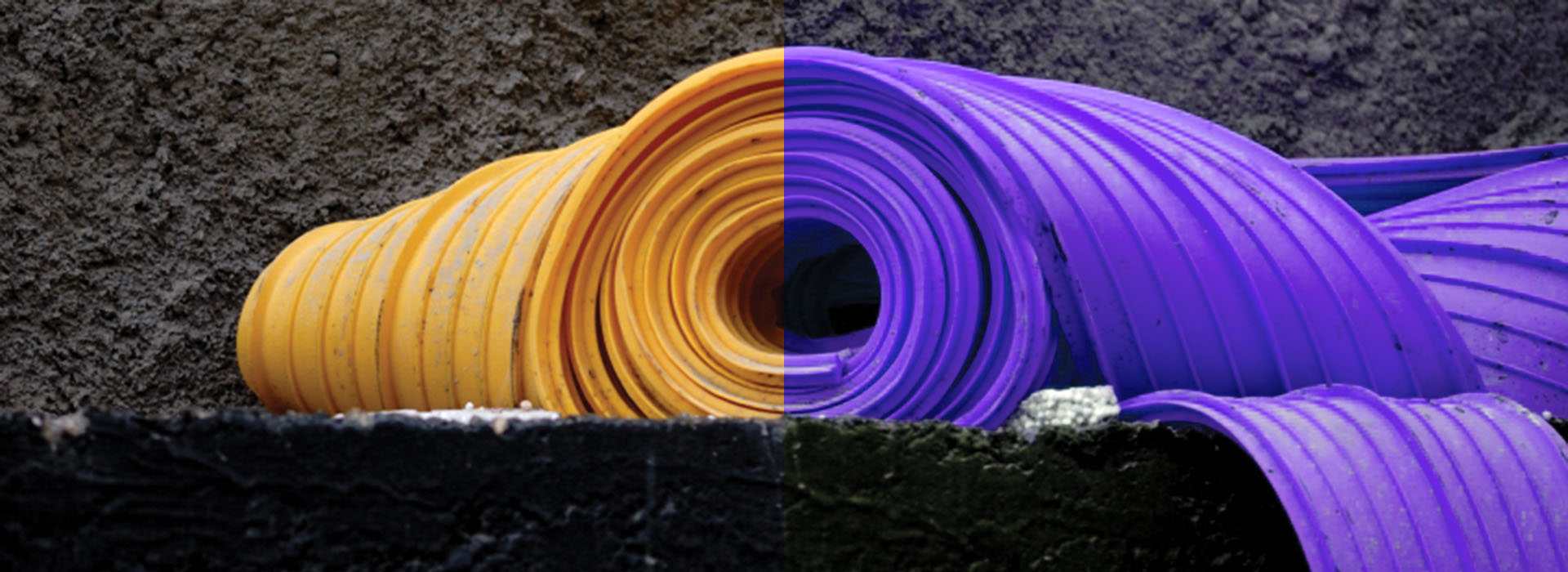

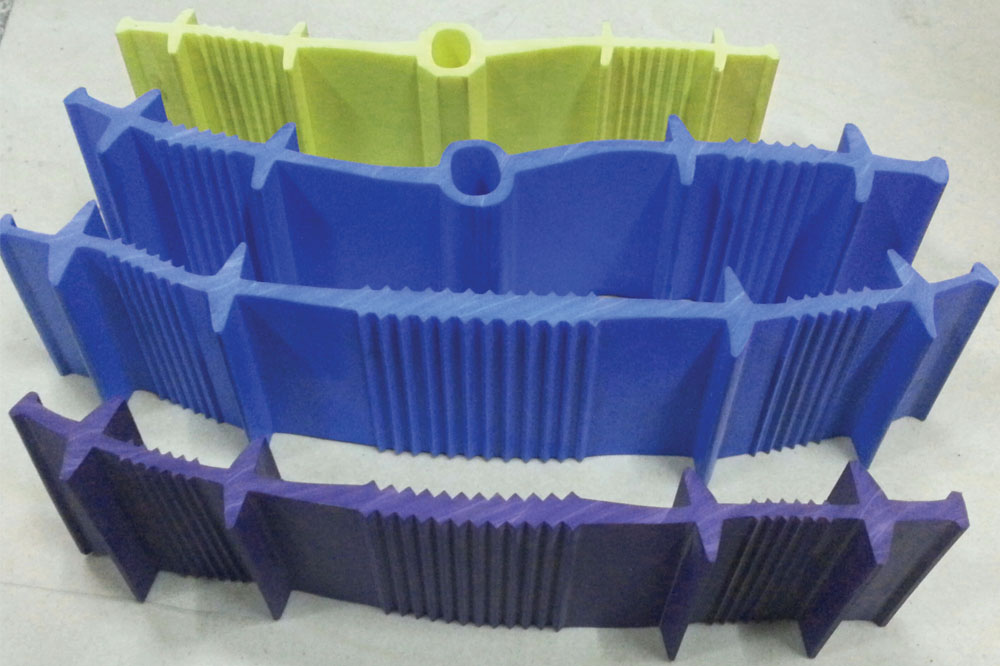

They are made of flexible PVC or TPV / TPE-R.

Concrete, like all materials, expands and contracts when the temperature fluctuates. To accommodate these changes, expansion joints are installed at regular intervals throughout the slabs and walls. PVC waterstops are recommended to stop leakage positively through construction and expansion joints in concrete structures.

They are required whenever concreting is to be made in two phases (between slab and slab or slab and wall or wall and wall). Nearly all large-scale concrete structures: reservoirs, locks, dams, aqueducts, bridges and deck abutments, culverts, tunnels, etc.—usually have waterstops installed during construction. Residential jobs also use waterstops, but usually, only at the cold joint between the footer and the foundation. They are used in environments with heavily polluted water or corrosive chemicals such as wastewater treatment facilities, or the primary and secondary containment structures surrounding refineries, sludge ponds, tank farms, etc.

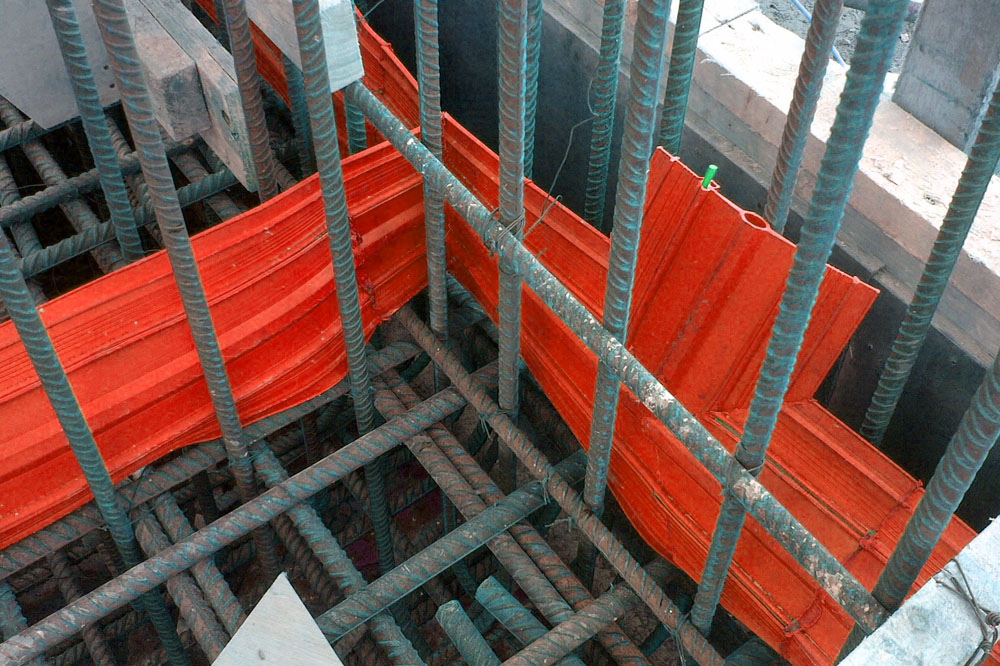

PVC Waterstops are installed within the reinforcing steel before concreting.

They are tied to the reinforcement steel bars with steel wires through the holes in the waterstop.

Installing the waterstops must be done before the concrete is placed. One side of the waterstop is embedded in the concrete during the first pour, with the other side temporarily exposed. When the next pour is made, the other half of the waterstop is encased in concrete. The centerline of the waterstop should be aligned with the center of the joint.

It is fastened to the vertical rebar or form ties to keep it in place. During the pour, workers must ensure good consolidation around the waterstop, as voids next to the waterstop can significantly compromise its water stopping ability.

Horizontally placed waterstops in slabs require particular attention, as it s difficult to get concrete to flow into the gap between the bottom of the stop and the top of the forming bed. Most waterstops are ribbed, or have a thicker -dumbbell- of material on the ends to keep them in place and ensure maximum water-sealing performance. Profiles with a -bubble- in the middle of the strip are best for joints with lots of movement.

Levajoint Waterstops are available in different sizes and types.

Several factors must be considered when selecting a waterstop: joint type and joint movement, hydrostatic pressure and chemical exposure.

Plain Web & centre bulb.

Exterior & Interior.

Levajoint PVC Waterstops Catalog.

Levajoint PVC Single Dumbbell Waterstops Catalog

Levajoint PVC Dumbbell Waterstops Catalog

Rayjoint PVC Waterstop Catalog

Levajoint TPV / TPE-R Waterstops Catalog

Levajoint TPV / TPE-R S Dumbbell WaterstopÂ

Levajoint TPV /Â TPE-R Dumbbell Waterstops CatalogÂ

Levajoint PVC waterstops chemical resistance

evajoint & Rayjoint TPV / TPE-R Waterstop Chemical Resistance

Levaprofile PVC & /or TPV / TPE-R Detailed Catalog (more than 550 shapes)

+9613260989

+9611690594

40 Street 86, Sector 7, Industrial City

Bauchrieh, Beirut, Lebanon